VATS and PASSKey Vehicle Anti-Theft

Systems

General Information

The Pass-Key, Pass-Key II, or VATS, as it's called in earlier GM

vehicles, uses a resistor mounted in the key blank to confirm that the

correct ignition key is being used to start the engine. Many

people call the resistor pellet a "chip" due to the common

misconception that it is some sophisticated digital circuit to identify

the key to the car. Not quite. It is not a “chip” of

silicon as is customarily used for integrated circuits, but merely a

block of carbon appropriately sized to have a desired electrical

resistance.

GM mixed about fifteen different resistance values in their pinning

codes to add another factor to make vehicle theft more difficult.

The resistor blocks are staked into the key bodies, just between the

key bow and pinning cuts. If you desire a replacement key for a

VATS equipped vehicle, they are available through almost any GM

dealership. These are usually priced about 3 times higher than

the same key can be purchased at any reputable locksmith. If you

have a VOM (multimeter), you can measure the resistance of the pellet

and inform the locksmith of the blank you will need, or simply allow

them to test and match it.

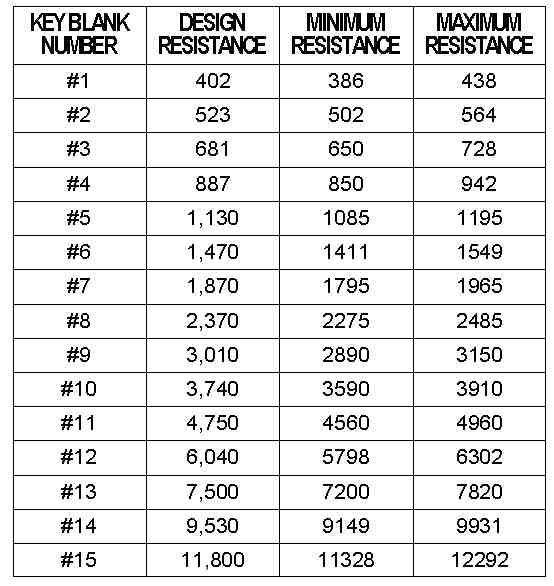

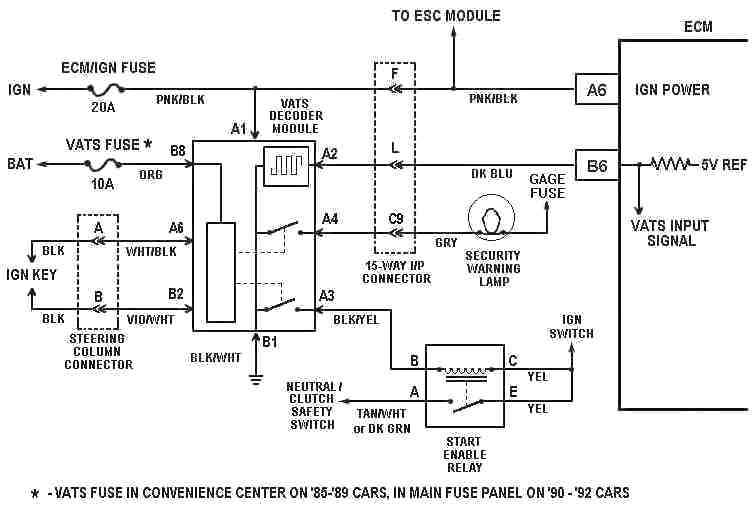

Vats Key Codes & Resistances

(Ordered in KEY BLANK numbers from 1

to 15, Resistances in Ohms)

System Operation

When the system is operating in normal mode, the VATS decoder reads the

correct resistance during cranking. The module grounds the Start

Enable Relay coil. When the start enable relay contacts close,

voltage is allowed to the "S" terminal of the starter. The VATS

module also sends an enable signal to the ECM. This signal allows the

ECM to operate the fuel injectors during cranking. The SECURITY

light will also illuminate for approximately five seconds, then turn

off and remain off.

If an incorrect or no key resistance is read by the VATS decoder

module, the module will shut down the start enable and ECM signal

outputs for 4 minutes. The SECURITY light will flash during the

cranking attempt, and will remain on during the 4-minute

duration. Even if the correct resistance is read within that 4

minute duration, the VATS module will not operate the relay or signal

the ECM..An error code.53 will also be set if the proper signal is not

being received on CKT 229 by the ECM when the ignition is turned

ON.

If an incorrect resistance is detected by the VATS module after the

engine is running, the VATS module will allow the vehicle to be

restarted, even with an existing failure. The SECURITY lamp will remain

on to warn the driver that a VATS system fault is present. However,

this also means that the car can be started w/o a correct key

resistance, and is therefore vulnerable to theft. An error code.53 will

also be set by the ECM in this mode.

NOTE -This error code does not store

in VRAM memory, but is only present while the condition exists, and is

useful as a diagnostic tool in troubleshooting VATS systems.

To signal the ECM that a correct key resistance is sensed, the VATS and

PASSKey systems use a grounding square wave at a 30Hz rate. The VATS

module uses an NPN output transistor to pull down (ground) the 5 VDC

reference voltage presented by the ECM on terminal B6. The reference

signal must be alternately grounded and allowed to be pulled up by the

ECM internal resistor 30 times per second (30 Hz) and at a 50% duty

cycle. This method was selected to prevent the simple powering or

grounding of an ECM input to enable the fuel injectors. The

signal is only needed during cranking to enable the injectors.

Once the engine is running, the VATS signal can be removed and the

engine will continue to operate normally, although with the SECURITY

warning lamp on.

The PASSkey-II signal is a similar square-wave pulsed-ground, but at a

50Hz rate, 50% duty cycle.

Circuit Description

The system uses two leaf contacts in the outer end of the ignition lock

cylinder to connect to the resistor pellet embedded into the key blank

just below the bow. The wiring from these leaf contacts travels down

along the steering column wire harness, where it connects to the

vehicle harness at the base of the column. Usually, the VATS

wiring in the column is in an orange covered cable, sometimes black,

and has a lone two-wire connector (no other circuits in the

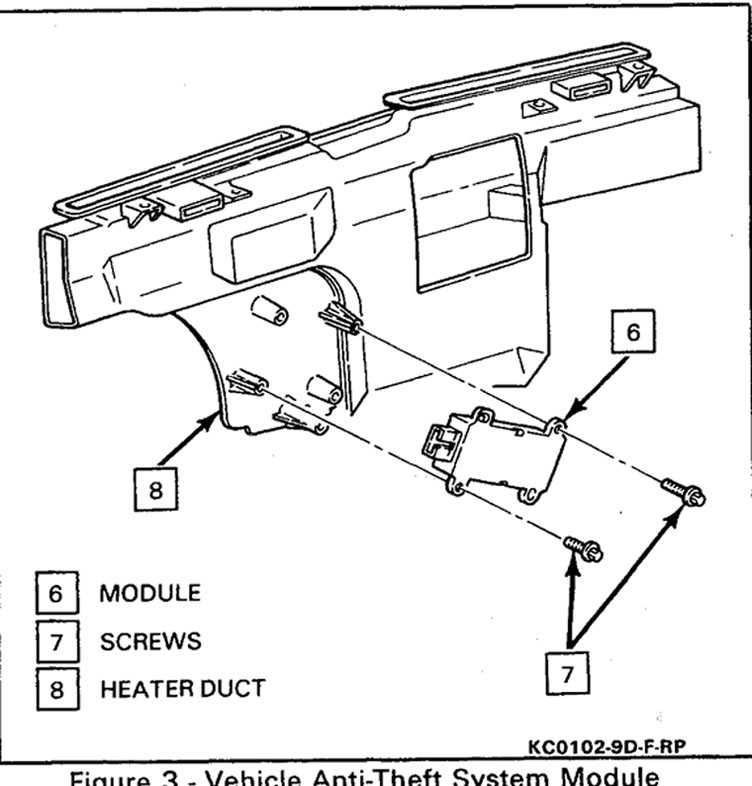

cable). The circuit continues from there to the VATS decoder

module via purple/white and white/black wires. The VATS decoder

module is located beneath the dash in the LH foot well, near the kick

panel.

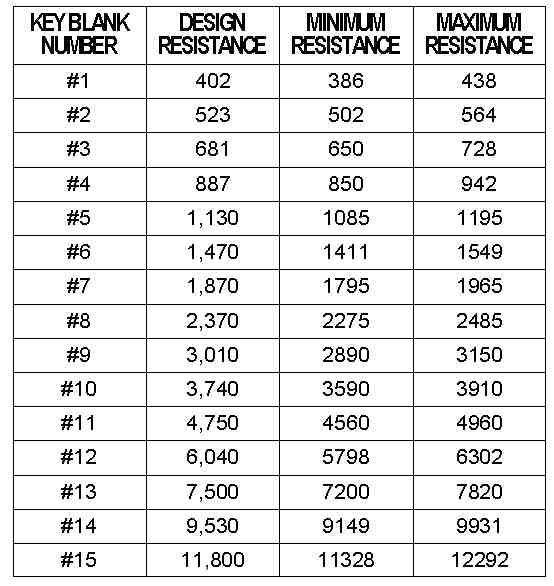

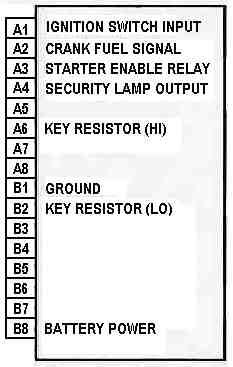

The VATS decoder module has sixteen connector pins, but uses only eight

wires:

An orange wire from B+ for a constant 12VDC to pin

B8;

A purple/white and a white/black wire from the key

contacts,

A pink/black wire from the ECM/IGN power fuse to pin

A1;

A dark blue wire connected from pin A2 to the ECM

pin B6;

A gray wire to the “SECURITY” lamp in the instrument

panel from pin A4;

A yellow/black wire to the start enable relay

operating coil ay pin A3;

And a ground on a black/white wire at pin B1.

NOTES

-

Circuit 229 used a dark blue wire in 1988-90, and the circuit passes

through the C207 connector between the ECM and dash harness.

Earlier

VATS systems may have used a white wire for this circuit, but the

connection to the ECM on pin B6 and schematic is the same.

Some systems may use two white wires

between the lock cylinder and VATS decoder module.

The key resistance wires may be encased

in a black covering, or an orange covering.

Diagnosis & Test Procedures

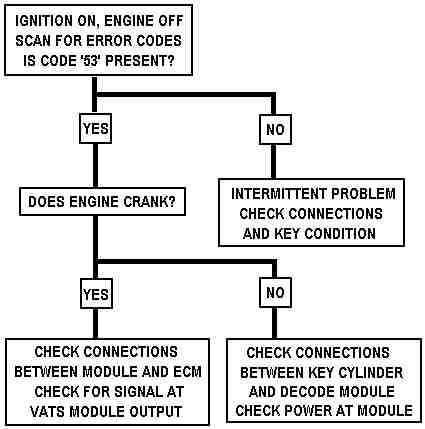

If the engine WILL CRANK and a code 53 is displayed, that indicates

that the VATS decoder module has detected a correct key resistance, and

has grounded the relay coil negative wire for the start enable relay,

but that the ECM is not receiving the VATS signal from the

module. That can be caused by either a failure of the VATS module

output which generates the signal, or Circuit 229 between the VATS

module and ECM is open or shorted to ground.

If the engine DOES NOT crank and a code 53 is displayed, that indicates

that the VATS decoder module has not detected the correct key

resistance, and therefore has not enabled the start enable relay, or

there is an incorrect starting procedure.

It is common for the leaf contacts and/or the resistor pellet on the

key bow to become contaminated to the point where the VATS decoder

module cannot correctly sense the pellet resistance, or cannot sense

any resistance at all. This would usually cause a no crank/no

start situation. Cleaning the key pellet and leaf contacts can

frequently restore system operation. Because of the risk of

contamination and other reasons, NO liquid lubricants should ever be

used on the ignition lock cylinder. The generally accepted

lubricant for ANY lock cylinder, whether a plate or pin type mechanism,

is powdered graphite ONLY. This especially applies to VATS

ignition lock cylinders.

It is also common for the two wires from the ignition lock cylinder

contacts to break due to the necessary flexing which occurs every time

the ignition lock is moved. This can usually be diagnosed by

measuring key pellet resistance at the VATS module or at the connector

at the base of the steering column.

There is a small two-wire connector in the upper bowl of the steering

column which can become damaged or disconnected as well, since

clearance between moving parts in the upper column bowl are

minimal.

The connector at the base of the steering column can fail if subjected

to stress, moisture, or movement if the lower bolster trim is not

in place.

The connector at the VATS decoder module is generally reliable, and the

connection at the start enable relay is also relatively safe from

interference and reliable. However, all connections should be

checked when diagnosing the system since any connection can fail or add

resistance to the circuits. The start enable relay itself is a

mechanical device, and can fail after prolonged use.

The following diagrams and charts may be useful in understanding and

diagnosing the system: