4L60E Repair

Guide - Disassembly

TRANSMISSION

DISASSEMBLY

Place the transmission on a sturdy workbench.

Remove the

transmission

mounting bell housing. This is not a task for a bargain

tool. The

Torx fasteners used to assemble the bell to the trans have a T-45

recess, and are not only torqued to a high level but have had adhesive

applied. Beyond that, they may have suffered seizure and galling

upon

installation or since, and will require significant torque to break

free. Use a good quality, undamaged Torx driver bit. Penetrating

oil

applied well in advance and heat on the case areas surrounding the

bolts will make the job much easier. This one step can turn the

project into a nightmare if not done successfully.

Remove

the transmission oil pan and filter.

Remove

the wire harness and main electrical connector socket. The socket

has

four locking tabs which need to be compressed inward to allow the

socket to be pushed into the transmission.

Remove

the TCC pressure signal solenoid (if equipped) retaining clip, then

slide the

solenoid from the valve body.

Remove

the TCC solenoid retaining bolts and slide the TCC solenoid valve out

of the pump body.

Compress

the pump pressure relief valve cap inward slightly against the springs,

then remove the valve snap ring.

Remove the valve body, reverse

boost spool, both

springs,

and internal pressure control/regulator valve spool. The

entire pressure control and boost valve can be left in place

until the pump is removed, but removing it now will allow more oil to

drain out while the bench is already full of contaminated oil.

Remove

the valve body bolts and the lower valve body. Secure the work

area so

that all seven of the check balls will be contained when removing the

plate. Take care to release the lower separator plate

gasket. Even if

you plan to replace the gasket, it will be easier to remove the gasket

in one piece than to clean off all remnants of the gasket from the

valve body or separator plate.

Remove the 2nd gear accumulator bolts

and accumulator.

Remove

the three bolts from the stamped steel plate near the left rear corner

of the valve body, remove the three accumulator body bolts, then

remove the separator plate. There will be at least one additional

check ball to capture when the plate is removed. The second check

ball

in the upper valve body should be retained in a cage assembly, but may

be loose. With the separator plate removed, remove the accumulator

spring.

Remove

the pump housing bolts and carefully pry the pump out of the front of

the case. There are pump pullers designed specifically for this

purpose, but a careful use of a large flat bar will coax the pump and

its sealing ring out of the front cavity bore with no damage.

Prying

between the pump and input drum and/or the gaps at the bottom of the

transmission case should get it moving forward. Be careful to avoid

damage to the pump gasket and case machined surfaces.

Remove

the band anchor pin from the upper valve body area. A strong

magnet

works well for this. This should relax the band adequately to

allow

removal of the reverse input drum assembly.

On the exterior of the right side of

the transmission case, clean the area surrounding the 2-4 band servo

cover. Compress the outer cover for the 2-4 servo inward, then

remove

the lock ring. Slide the cover and servo assembly outward.

Remove the input shell and drum/clutch assembly. Pull straight outward

and support the weight of the assembly as it disengages from the

reaction shell and input planetary set.

Remove the band. These parts should now be sitting on the bench:

Remove

the yellow shaft lock retaining ring from the output shaft, then remove

the input sun gear. You should also be able to remove the VSS or

speedometer thimble, tail shaft housing (if equipped), and output shaft

at this time.

Remove

the input planetary set as an assembly.

Remove

the reaction sun shell. There is a thrust washer visible on the

front,

and another behind the shell which should be attached to the reverse

sprag hub. Be aware that it may fall out as you remove the shell

and

that this is no cause for alarm.

This reaction sun gear spline had lost the rear retaining ring from the

groove and showed some spline damage - The spline does not fit new sun

shell hub easily.

Remove

the large lock ring holding the low-reverse clutch support, then lift

out the support plate. There is no spring force behind the

support, so

the lock ring should disengage easily.

Remove the low-reverse (reaction)

planetary assembly as a unit.

Remove the low-reverse clutch stack

and low-reverse planetary ring gear, then the support plate behind

that. Remove the planetary ring gear support lock ring.

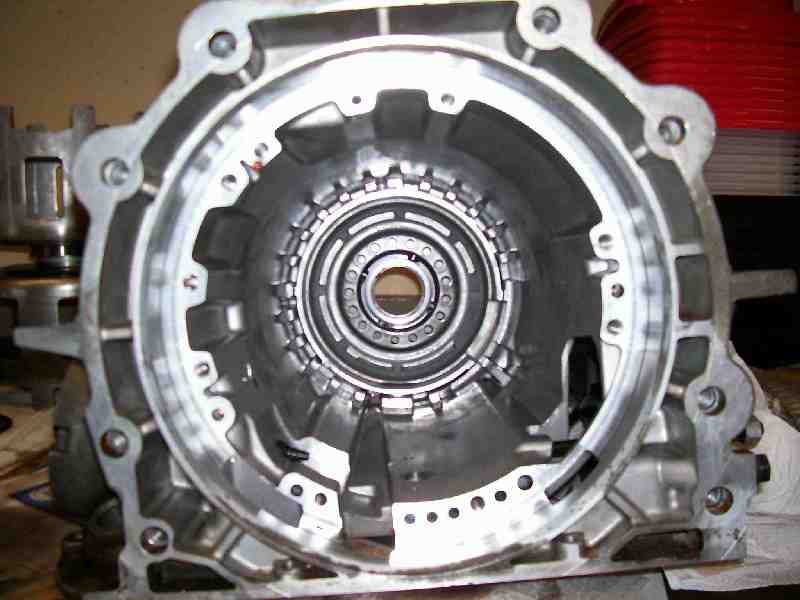

You should now be looking at the

low-reverse clutch apply assembly. Compress the low-reverse clutch

spring pack with a suitable tool, then remove the retaining ring from

the hub. Relax the compression on the spring pack and remove all

the

parts. The case should now be essentially a bare casting, other than

some seal rings, bushings, and the parking pawl and shift linkage

remaining in the case. This is an appropriate time to clean the

case

exterior thoroughly in preparation for assembly.