NOTE: On

Astro and Safari AWD vans, the cross member which

mounts the rear of the transmission also carries the anchors

for the fixed ends of the torsion bars. Some additional steps

will be necessary to enable the cross member to be removed

safely.

Apply

penetrating oil to both torsion bar anchor/adjustment screws, then back

off the screws while counting the number of turns. Make a note of

this

so they can be adjusted to the same position upon assembly. Once

tension is relaxed from both torsion bars, remove the cross member and

slide the bars from their sockets at both ends.

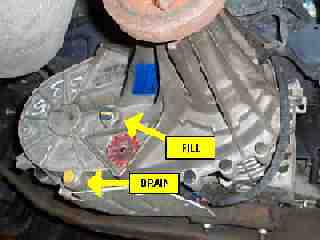

Drain the transfer case (if

equipped). On AWD and 4WD vehicles with a floor mounted shift lever for

the transfer case, remove the interior floor trim and disconnect the

shift linkage.

Drain the transfer case (if

equipped). On AWD and 4WD vehicles with a floor mounted shift lever for

the transfer case, remove the interior floor trim and disconnect the

shift linkage.  Some vehicles will have additional

brackets or supports for the transmission and/or transfer case.

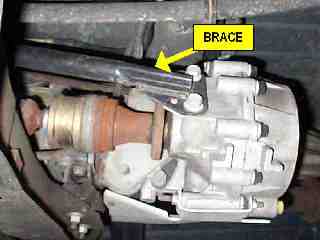

Some vehicles will have additional

brackets or supports for the transmission and/or transfer case.  For AWD and 4WD

vehicles, remove the

skid plate from the bottom of the case, and disconnect all electrical

connectors and the vent hose. Support the transfer case on your

trans

jack. Unbolt the transfer case from the transmission adapter and remove

it.

For AWD and 4WD

vehicles, remove the

skid plate from the bottom of the case, and disconnect all electrical

connectors and the vent hose. Support the transfer case on your

trans

jack. Unbolt the transfer case from the transmission adapter and remove

it.